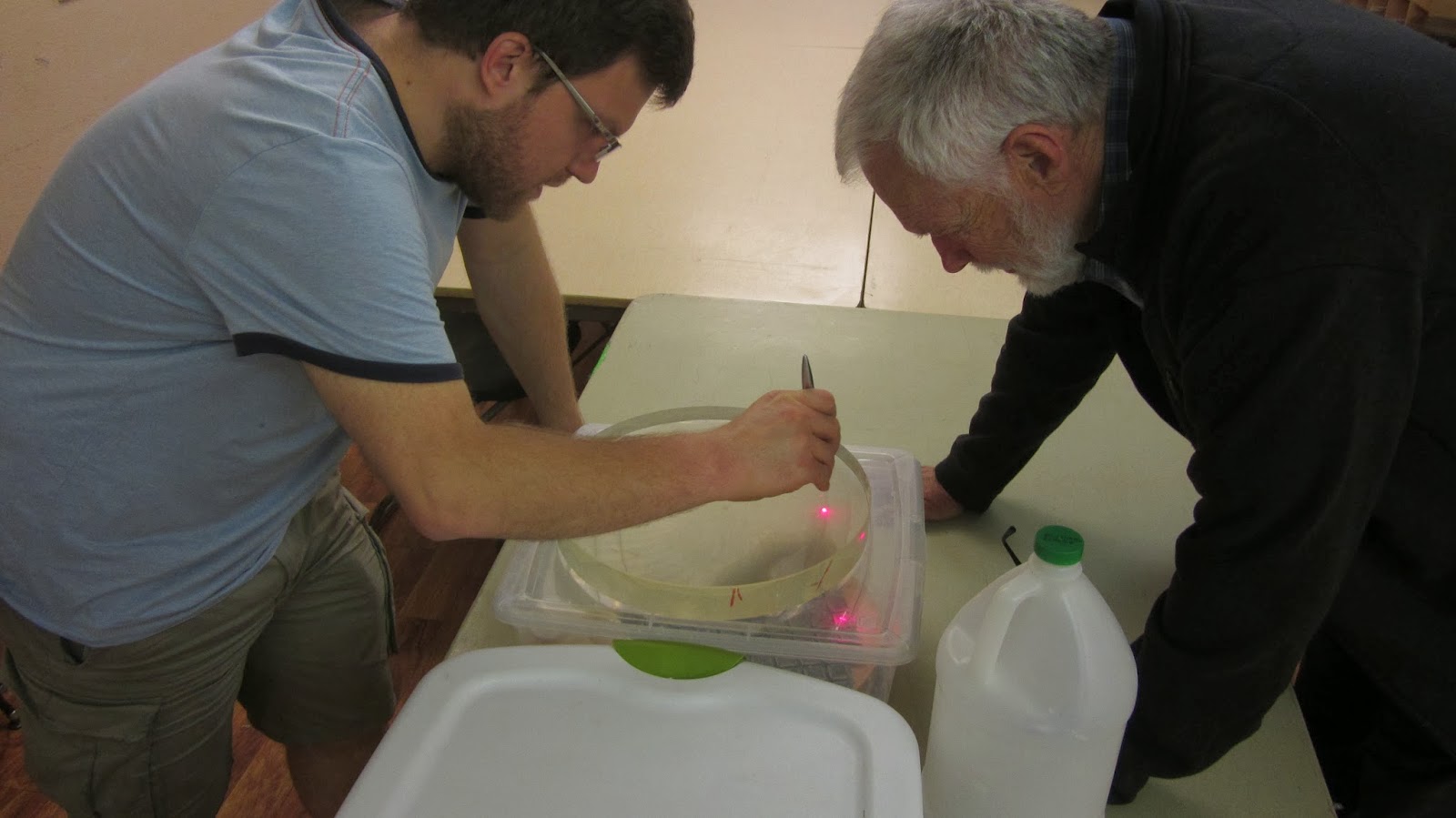

140326 Jerry passed on these photos of the time that JoeD was 2" hole sawing through the 10" mirror that Jerry is making:

JerryW says:

We are using a steel tool to core a 2 inch

diameter hole in the back of a 10 inch f/4 Pyrex mirror. The mirror

is at the #120 stage of grinding with the same size grit used for

coring. The cutting at this stage will stop about 3/16 of an inch

from the front surface and will be completed from the front surface after

polishing and figuring. The work was done using Joe D's drill

press.

Showing posts with label telescope. Show all posts

Showing posts with label telescope. Show all posts

Wednesday, March 26, 2014

140325 SBAU Telescope Workshop

140325 SBAU Telescope Workshop

Sam of Westmont, TomW, JerryW, TimC, JoeD, MikeChibnik (also member VenturaCoAS; SB Raytheon EE), ChrisU, EdK, TomT

MikeC showed his wooden stand for grinding or polishing.

TomW pouring 6" pitch lap tool for EdK into silicone mold sitting on the 12.5" mirror with Sam of Westmont observing work.

Tom showing curvature of pitch lap tool since it is pre-formed while on top of mirror in perfect pitch lap mold.

Sam will take a 10" mirror from TomW and work it to F/4 with porcelain tool.

ChrisU donating some wood circular blanks for grinding / polishing tools and a mirror holder for Sam 10" mirror.

JoeD announced SBAU Messier Marathon this Saturday, March 29, but weather will be a question. Also, talking paracorr optics with TimC and MikeK.

Some other odd stuff mentioned this evening:

-Schmidt was a SBAU President.

-At one time the Telescope workshop had over 10 people at one time. Tonight's nine is a new recent high number.

-Warren Bitters used to bring daughters to telescope workshop.

|

| JoeD holding TimC's 8" pre-scratch; MikeC, TomW, Sam |

|

| The Crawford Comet |

Update from TimC:

On 3/26/2014 10:53 PM, Tim Crawford wrote:

The top photo is of the original scratch from Tuesday's session. The second (sorry for the lack of focus) has been filtered to enhance it a bit. You can see I made a lot of progress in ridding the surface of this gouge. I agree with Jerry- this is the result of a small piece of tile that exfoliated from the tool during 5 micron grinding. Too bad- I was almost finished. Great lesson in this though. Suggestions from you were most helpful! Here's how it went:I decided to put in about 10-15 minutes with 5 micron. Results were dismal. The same happened with 12 micron. So, reluctantly I went back to 500 silicon carbide. Here I had modest results and I realized in time I would get rid of most of the defect but not fast enough for my liking. So, I switched to 320 aluminum oxide. Total time with all grits was around 1 1/2 hour. The enhanced photo shows there are still traces of the gouge, but in reality it is diminished through a loupe. The main defects now are 2 main big chips (?) that are evident in the photo. The plan is to now resume with 500 silicon carbide for up to 2 hours. Following will be the subsequent steps from 12-5 micron. Total time could be 6 more hours but I may push it. I apologize for holding up the project. I am still learning so much here. As I said, I much appreciate the comments and support in this project. I am just not sure in the end if I will rid the surface of the entire defect. The defects in my estimation are around the 70 zone, so it can effect the image. After 6 hours plus polishing it will be minimal I believe. The greatest lessons here are to take care of the environment we are working in. It has become apparent keeping a clean environment is crucial to success, and even then there are just freak events like chipping of tile that may happen. (As a result of this I took the tool down to the lab and used a wheel to bevel the outside perimeter of the tile tool. ) The second lesson is to remember that no matter what we can always backtrack and redo any disasters that may happen on the journey to first light. Patience and good humor will be two tools we must include in our toolboxes. Well, enough for now- I'll try to keep you informed of progress, but for now it appears to be just a matter of time......and time heals just about everything.T

Monday, March 17, 2014

140316 TimC next meeting:

On 3/16/2014 12:12 PM, Tim C wrote:

> We are scheduling a workshop for this upcoming Tuesday, March 18th. There may be a couple of things happening this Tuesday. We will have a tester available to see progress of existing mirrors. I think we are going to take a look at a 10" mirror to see its shape right now. This will dictate which direction to take looking forward. As we have somewhat of a knowledge of this mirror, I believe it may be suggested to first take it back to a sphere, then work on figuring the mirror to a paraboloid shape. For now we will get a great idea of the shape. Stroke shapes, duration of strokes to use to get back to a sphere will be suggested.With vast knowledge available to you from our experts, suggestions may be made to guide the figuring to a parabola right from this state of the wavefront! It's really tricky to do this though. If you are not familiar with figuring, it may be best to go directly back to a sphere. Then, after becoming more familiar with the feel of the pitch over the mirror, you will feel more at home and figuring a little more understandable. For those of you that wish to know more about figuring, you may not want to miss this. Unfortunately, I will most likely not make the class this week due to a busy workload. If I can get there though, I will be grinding on our donated 8" one last hour before I go to polishing. It seems like our little workshop is doing magnificently well. Please feel free to join in if you want!

> T

> We are scheduling a workshop for this upcoming Tuesday, March 18th. There may be a couple of things happening this Tuesday. We will have a tester available to see progress of existing mirrors. I think we are going to take a look at a 10" mirror to see its shape right now. This will dictate which direction to take looking forward. As we have somewhat of a knowledge of this mirror, I believe it may be suggested to first take it back to a sphere, then work on figuring the mirror to a paraboloid shape. For now we will get a great idea of the shape. Stroke shapes, duration of strokes to use to get back to a sphere will be suggested.With vast knowledge available to you from our experts, suggestions may be made to guide the figuring to a parabola right from this state of the wavefront! It's really tricky to do this though. If you are not familiar with figuring, it may be best to go directly back to a sphere. Then, after becoming more familiar with the feel of the pitch over the mirror, you will feel more at home and figuring a little more understandable. For those of you that wish to know more about figuring, you may not want to miss this. Unfortunately, I will most likely not make the class this week due to a busy workload. If I can get there though, I will be grinding on our donated 8" one last hour before I go to polishing. It seems like our little workshop is doing magnificently well. Please feel free to join in if you want!

> T

Thursday, March 13, 2014

140312 re: Porter Garden telescope

On 3/13/2014 8:33 AM, Joe D wrote:

Hi All,

FYI I did contact the people making the Porter and every time I spoke with them it got more expensive. Really expensive. In the last conversation they wanted around $7000 for part of a focuser.

Eventually I made a maple base, which I do think came out pretty nice and in reasonable harmony with the original art deco bronze. (FYI we did not have an original base to make a casting from.) I also had to make a focuser assembly, with 20+ pieces this worked well but did not look art deco. We had a chance to cake a copy of an original focuser (some other museum or club had an original and allowed us to borrow a mold) but at that point we had been on the project over 2 years and we all wanted to wrap it up and the person who was going to spearhead the casting part of the project bailed.

FYI we did use it one night, it had a great image (considering that it has a Tim C mirror, there is no surprise here) but was quite awkward to aim and use. It is way to heavy & bulky to move around often. Really it was not a great scope under the start but as Indiana Jones would say, "It belongs in a museum!"

The Porter Scope restoration was an interesting project for me but I consider it DONE, especially considering that the museum is no longer displaying it to the public. Still if anyone wants to pursue this, I will be happy to turn over all my notes.

Cheers,

Joe

On Mar 12, 2014, at 9:19 PM, Tim C wrote:

This is good news. Interesting. I know the cost of the replica Porter Scope was somewhere in the vicinity of 40,000. Joe D contacted these people once( I think it was Joe). He had a difficult time dealing with them to get"part" of the scope redone. It turned out I think to be much more than what was quoted to you for the base part, in fact, I'm sure of it. I hope we can discuss this further , especially with the powers that be. In the meantime Christopher, great work. You are an extremely interesting artist with seemingly a wealth of resources at your disposal. Please thank Nevin for his in depth reply to you. I do believe the Museum may be very interested in this development. In fact, I am CCing Javier R, who I hope you have had the pleasure of meeting already ( I think you have). We'll see how this all shakes out. I am just not sure how much interest this will have at this particular time from the Museum's position. They have a lot of irons in the fire. We may want to let the club officers know through Tom T of this. Again, thank you for this news regarding this wonderful piece in the Museum's possession.

T

On Mar 12, 2014, at 2:00 PM, christopher u wrote:

Hi Guys,

I wrote Nevin Littlehale to inquire about the cost for replacing the bronze base of the Porter Garden Scope. We had spoken about it a while back and I had forgotten to ask earlier. It seems much less expensive a prospect than I had though (approximately $700us see below). It really would be a beautiful addition to the museum.

I'm not sure how and to whom the information could be forwarded.

Best,

C.U.

From: Christopher U

Date: Mon, Mar 10, 2014 at 12:21 PM

Subject: Garden telescope base restoration estimate?

To: Nevin Littlehale

Hello Nevin,

It's Chris U from painting at SBCC. I was speaking with some people from an astronomy club Santa Barbara Astronomical Unit. They told me that the SBMNH has an incomplete 1920's Porter Garden Telescope. They just need to remake the base which is missing completely. It is a beautiful and important object so...

-They were wondering if possible and approximately how costly it would be to replicate the base. What do you think?

RESPONSE FROM NEVIN:

To make something like that I will have to make a model and then pull a mold off of it then cast it in Bronze. I could also design it in Autodesk inventor and print it then cast it. How soon do they need this? Can I come and look at the original and get some spec's on it? All told it shouldn't be more than $700.00.

http://www.novacon.com.br/odditycameras/portergradene.htm

Hi All,

FYI I did contact the people making the Porter and every time I spoke with them it got more expensive. Really expensive. In the last conversation they wanted around $7000 for part of a focuser.

Eventually I made a maple base, which I do think came out pretty nice and in reasonable harmony with the original art deco bronze. (FYI we did not have an original base to make a casting from.) I also had to make a focuser assembly, with 20+ pieces this worked well but did not look art deco. We had a chance to cake a copy of an original focuser (some other museum or club had an original and allowed us to borrow a mold) but at that point we had been on the project over 2 years and we all wanted to wrap it up and the person who was going to spearhead the casting part of the project bailed.

FYI we did use it one night, it had a great image (considering that it has a Tim C mirror, there is no surprise here) but was quite awkward to aim and use. It is way to heavy & bulky to move around often. Really it was not a great scope under the start but as Indiana Jones would say, "It belongs in a museum!"

The Porter Scope restoration was an interesting project for me but I consider it DONE, especially considering that the museum is no longer displaying it to the public. Still if anyone wants to pursue this, I will be happy to turn over all my notes.

Cheers,

Joe

On Mar 12, 2014, at 9:19 PM, Tim C wrote:

This is good news. Interesting. I know the cost of the replica Porter Scope was somewhere in the vicinity of 40,000. Joe D contacted these people once( I think it was Joe). He had a difficult time dealing with them to get"part" of the scope redone. It turned out I think to be much more than what was quoted to you for the base part, in fact, I'm sure of it. I hope we can discuss this further , especially with the powers that be. In the meantime Christopher, great work. You are an extremely interesting artist with seemingly a wealth of resources at your disposal. Please thank Nevin for his in depth reply to you. I do believe the Museum may be very interested in this development. In fact, I am CCing Javier R, who I hope you have had the pleasure of meeting already ( I think you have). We'll see how this all shakes out. I am just not sure how much interest this will have at this particular time from the Museum's position. They have a lot of irons in the fire. We may want to let the club officers know through Tom T of this. Again, thank you for this news regarding this wonderful piece in the Museum's possession.

T

On Mar 12, 2014, at 2:00 PM, christopher u wrote:

Hi Guys,

I wrote Nevin Littlehale to inquire about the cost for replacing the bronze base of the Porter Garden Scope. We had spoken about it a while back and I had forgotten to ask earlier. It seems much less expensive a prospect than I had though (approximately $700us see below). It really would be a beautiful addition to the museum.

I'm not sure how and to whom the information could be forwarded.

Best,

C.U.

From: Christopher U

Date: Mon, Mar 10, 2014 at 12:21 PM

Subject: Garden telescope base restoration estimate?

To: Nevin Littlehale

Hello Nevin,

It's Chris U from painting at SBCC. I was speaking with some people from an astronomy club Santa Barbara Astronomical Unit. They told me that the SBMNH has an incomplete 1920's Porter Garden Telescope. They just need to remake the base which is missing completely. It is a beautiful and important object so...

-They were wondering if possible and approximately how costly it would be to replicate the base. What do you think?

RESPONSE FROM NEVIN:

To make something like that I will have to make a model and then pull a mold off of it then cast it in Bronze. I could also design it in Autodesk inventor and print it then cast it. How soon do they need this? Can I come and look at the original and get some spec's on it? All told it shouldn't be more than $700.00.

http://www.novacon.com.br/odditycameras/portergradene.htm

Tuesday, March 11, 2014

140309 TimC mirror area Cosmos

On 3/9/2014 10:34 PM, Tim C wrote:

We are scheduling a workshop for this week, March 11th. Bill, please could you have the side gate open. Thank you much. I will not be attending this week, but Jerry Wilson will do the honors. Attend if you wish. There is a chance the outreach scheduled for this week may be cancelled and if that is the case we'll all be back on track. It was wonderful to see Christopher and his dad Frank at this month's star party. The "flaming tomato" is sprouting wings! If you have an 8" scope and you get a 10" scope, how much more " light grab" will you achieve with the 10 "? Let's ball park this- pi r^2 = area. There for r^2= 4^2= 16. That is the shorthand area of the 8" scope. The 10" is 5^2=25. That is the shortcut area of the 10" mirror. So, if I have it right it's like 64% s'more light grab with the 10" mirror vs. the 8". This becomes important as you progress through the art of mirror making. Everyone hears of aperture fever. In reality though, it is reasonable to think of the relationship of light grab vs. what you are willing to drag to a location to view the stars. In the end, it is perfectly true that the scope that is right is the one you will use the most. I will argue these are the reflectors between 6" and 14". Above those diameters one must use imaginative and intuitive ways to use the larger scopes. But.... I digress.... It's just so much fun!! I just got finished watching "Cosmos" on one of about 5 different networks. Regardless if a mere President of the United States introduced it, I was really moved by the end of the episode when our friend Neil DeGrasse Tyson showed a book with Sagan's signature and invitation. Very Powerful!!!!! Tyson is a great emissary. I'm sure you wish him well, as I do! T

Friday, March 7, 2014

From the Workshop...#3 by Tim C

From the Workshop...#3 (from SBAU newsletter, March 2014)

Tim Crawford

From the first two issues of “From the Workshop” we now know what it takes to begin grinding a mirror blank against its tool: the center of the mirror deepens and the edges of the tool wear as they become a perfect complement to the mirror. Now you may ask yourself "How deep do I make the center of my mirror?" In other words, “When should I stop grinding?” This, of course is up to you! What focal length do you want mirror to have? The focal length, F, is the distance from the mirror where parallel (distant) light comes into focus. Moreover, the depth of your mirror at its center determines F. It will also drive some of the design characteristics of your finished telescope, as we will see in future issues. In short, when you reach the desired depth at the mirror’s center, it is time to stop deepening your mirror! What follows are some straightforward “mirror mathematics.”

(1) The Focal Ratio. This number is nothing more than the ratio your mirror’s focal length, F, to your mirror’s diameter. For example, if you are working on an 8” (200mm) diameter blank and you want a focal length of 1000mm, the focal ratio is 1000/200 = 5. You would say that the focal ratio of your desired mirror is 5. Or, equivalently, you are crafting an F/5 mirror.

This ratio has a number of important consequences. One is that a smaller-focal-ratio mirror will have a shorter focal length and, as a result, a deeper center. It may not be obvious at this point, but this type of mirror will have a wider field-of-view. When used with shorter focal length eyepieces, a short focal length mirror will capture larger areas of the night sky. And it will do so with low power. Often this kind of mirror is used in what’s called a “richest field” telescope. Open star clusters are wonderful targets for this kind of telescope!

On the other hand, if you plan to do a lot of planetary viewing, a longer focal ratio mirror will suit you better. Here, with a comparable eyepiece, the longer focal length will supply the higher power needed in seeing details in, say, Jupiter or the Moon.

Keep in mind that there is no focal ratio that “does it all.” A comfortable focal ratio of F/4 to F/6 with focal lengths between 750mm to 1500mm both (a) keep you off tall ladders and (b) allow you to enjoy both ends of the “Planet-to-Cluster” viewing spectrum. I crafted and use a 10" f/5.2 scope and find it easy to use and carry about. It yields fine views of planets and deep sky objects that are within its grasp. So...you pick a number! How about an 8" mirror with an f/6 focal ratio?

In my next essay, I will discuss the mirror’s “radius of curvature" and some other terms that define how our finished mirror will behave optically. Till then, I wish you "clear skies," but only after we get some much needed rain!

Tim Crawford

From the first two issues of “From the Workshop” we now know what it takes to begin grinding a mirror blank against its tool: the center of the mirror deepens and the edges of the tool wear as they become a perfect complement to the mirror. Now you may ask yourself "How deep do I make the center of my mirror?" In other words, “When should I stop grinding?” This, of course is up to you! What focal length do you want mirror to have? The focal length, F, is the distance from the mirror where parallel (distant) light comes into focus. Moreover, the depth of your mirror at its center determines F. It will also drive some of the design characteristics of your finished telescope, as we will see in future issues. In short, when you reach the desired depth at the mirror’s center, it is time to stop deepening your mirror! What follows are some straightforward “mirror mathematics.”

(1) The Focal Ratio. This number is nothing more than the ratio your mirror’s focal length, F, to your mirror’s diameter. For example, if you are working on an 8” (200mm) diameter blank and you want a focal length of 1000mm, the focal ratio is 1000/200 = 5. You would say that the focal ratio of your desired mirror is 5. Or, equivalently, you are crafting an F/5 mirror.

This ratio has a number of important consequences. One is that a smaller-focal-ratio mirror will have a shorter focal length and, as a result, a deeper center. It may not be obvious at this point, but this type of mirror will have a wider field-of-view. When used with shorter focal length eyepieces, a short focal length mirror will capture larger areas of the night sky. And it will do so with low power. Often this kind of mirror is used in what’s called a “richest field” telescope. Open star clusters are wonderful targets for this kind of telescope!

On the other hand, if you plan to do a lot of planetary viewing, a longer focal ratio mirror will suit you better. Here, with a comparable eyepiece, the longer focal length will supply the higher power needed in seeing details in, say, Jupiter or the Moon.

Keep in mind that there is no focal ratio that “does it all.” A comfortable focal ratio of F/4 to F/6 with focal lengths between 750mm to 1500mm both (a) keep you off tall ladders and (b) allow you to enjoy both ends of the “Planet-to-Cluster” viewing spectrum. I crafted and use a 10" f/5.2 scope and find it easy to use and carry about. It yields fine views of planets and deep sky objects that are within its grasp. So...you pick a number! How about an 8" mirror with an f/6 focal ratio?

In my next essay, I will discuss the mirror’s “radius of curvature" and some other terms that define how our finished mirror will behave optically. Till then, I wish you "clear skies," but only after we get some much needed rain!

Thursday, March 6, 2014

140304

140304 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TimC, DmitriiZ, ChrisU

JerryW brought in motorized JMI focuser, w/o motor controller, to donate to 8” donated mirror telescope TimC is working on. TimC checking curve to see if it would fit 8” tube. Tim doing 5 micron polishing this evening.

Dmitrii brought in 12.5” mirror for evaluation. He thinks 12 hours of 12.5 micron polishing has been put in since the improper polish was used. A little scratch in the surface, but laser checking is otherwise fairly consistent across the mirror. Green higher power laser seems to give a sharp reflection off the surface. Jerry looking at Jean Texereau polishing chart with a curve of number of pits left as hours are put into polishing.

Some time was spent on inviting folks to an Apple icloud area to post photos, then looking at a 3D optical illusion of Saturn stored there.

ChrisU having trouble getting in touch with Newport Glass for cerium oxide. Jerry says China drove people out of business making the stuff, so now hard to get. CR Lawrence, National Abrasives, and Willman Bell may be other sources.

Attendees: TomT, JerryW, TimC, DmitriiZ, ChrisU

JerryW brought in motorized JMI focuser, w/o motor controller, to donate to 8” donated mirror telescope TimC is working on. TimC checking curve to see if it would fit 8” tube. Tim doing 5 micron polishing this evening.

Dmitrii brought in 12.5” mirror for evaluation. He thinks 12 hours of 12.5 micron polishing has been put in since the improper polish was used. A little scratch in the surface, but laser checking is otherwise fairly consistent across the mirror. Green higher power laser seems to give a sharp reflection off the surface. Jerry looking at Jean Texereau polishing chart with a curve of number of pits left as hours are put into polishing.

Some time was spent on inviting folks to an Apple icloud area to post photos, then looking at a 3D optical illusion of Saturn stored there.

ChrisU having trouble getting in touch with Newport Glass for cerium oxide. Jerry says China drove people out of business making the stuff, so now hard to get. CR Lawrence, National Abrasives, and Willman Bell may be other sources.

Tuesday, March 4, 2014

140302 TimC notice

On 3/2/2014 9:54 PM, Tim C wrote:

We are scheduling our workshop this week, February 4th, to continue our projects and further our endeavors in this fine craft of optics and scope building. There may be a few items to go over regarding some upcoming events. This I am going to leave open for discussion. We have an upcoming Astronomy Day, May 10th and possible "member's night" presentations we may offer up. I believe these are during the summer months of July and August. I know some have already signed up to do presentations. Maybe some of you have ideas ? I believe the time you will have to share your offering will be in the order of 15 minutes or so?

(Bill,... we really appreciate you having the Broder Building ready for us every week. I hope we leave it better than we find it. That is our wish.) I am thinking of not having a workshop the following week, February 11th. Some of us have already expressed this will be fine. I have scheduled an outreach for myself and will not be present. If any of you wish to still participate, let me know. It may be best though to just break for one week. The core members of the group I believe are okay with this. [Telescope Tuesday at the Camino Real Marketplace needs help as Chuck/Pat are doing another event.] This break does effect my plan to be polishing our donated mirror. It will set me back one week, but, I may do a little work at home. This will keep the project on time. I will be giving a time table for building our little 8" scope in the very near future. In the meantime, I know there are at least two other mirrors that will be in the polishing phase. In fact, get this- we will be polishing and figuring out 3 different mirrors at the same time very soon. No- make that 4! Two 12.5" mirrors, one 10" mirror and one 8" mirror. Come on Tom K. Make it 5! You know, there are some of you on the email list that have expressed interest in grinding a mirror. I can tell you, it is a worthwhile venture. It is really cool to look up and see a target in the night sky. But seeing it with something you personally handcrafted yourself- well it is dreamlike. You will step into the shoes of those who worked out the processes, painstakingly made contraptions to test them and lifted us all to see more than just the stars. People like John Dobson or Jean Texerau. Both have recently left us. They have lifted us to the eyepiece. It is for us to "look through". See you Tuesday....I want to say also, I am honored to be amongst you. T

Thursday, February 20, 2014

140218

140218 Telescope Workshop notes 730-9p Tuesday evening

Attendees: DmitriiZ, TomT, JerryW, TimC, EdK, ChrisU, DavidH (+M)

TomT asking JerryW how to set up Registax6 for stacking his 99 frame video of Jupiter. Used only a few frames to get a better view of Jupiter with a shadow or two on its face.

JerryW brought in Oculus All Sky Camera, a gift from his wife, which records the night sky at various shutter exposure times to catch meteors. He usually will set it to record 1 minute exposures, then there is a 5 second delay between shots.

TimC, after showing Madeline how to grind mirror and setting her up with coloring pens, is continuing aluminum oxide 12 micron grit grinding (polishing compound) on the 8” donated mirror. JerryW checked the surface with the loupe and called for another hour to be sure. But Jerry says you cannot really see the pits on the surface at this point, just put 3hrs in at each fine grit.

EdK has finished setting up his Celestron on the Losmandy tripod with the adapter at home.

DavidH brought in his older Celestron mount to start putting the motors in place.

ChrisU brought in 10” polished mirror and pitch tool that was made by ChuckMcP, but more figuring is needed per Jerry. Need to keep mirror and polishing equipment perfectly clean, away from old grit materials.

More photos posted at Flickr eventually:

Attendees: DmitriiZ, TomT, JerryW, TimC, EdK, ChrisU, DavidH (+M)

TomT asking JerryW how to set up Registax6 for stacking his 99 frame video of Jupiter. Used only a few frames to get a better view of Jupiter with a shadow or two on its face.

JerryW brought in Oculus All Sky Camera, a gift from his wife, which records the night sky at various shutter exposure times to catch meteors. He usually will set it to record 1 minute exposures, then there is a 5 second delay between shots.

TimC, after showing Madeline how to grind mirror and setting her up with coloring pens, is continuing aluminum oxide 12 micron grit grinding (polishing compound) on the 8” donated mirror. JerryW checked the surface with the loupe and called for another hour to be sure. But Jerry says you cannot really see the pits on the surface at this point, just put 3hrs in at each fine grit.

EdK has finished setting up his Celestron on the Losmandy tripod with the adapter at home.

DavidH brought in his older Celestron mount to start putting the motors in place.

ChrisU brought in 10” polished mirror and pitch tool that was made by ChuckMcP, but more figuring is needed per Jerry. Need to keep mirror and polishing equipment perfectly clean, away from old grit materials.

More photos posted at Flickr eventually:

Tuesday, February 11, 2014

140211

140211 SBAU Telescope Workshop, Tuesday, 730-9p

TimC,EdK,TomT

EdK brought in 14h? x 17w? framed astrophotography of M31, the (Princess) Andromeda Galaxy, created by Paul Winn...very beautiful. Ed is working on his Losmandy tripod adapter to the Celestron CGEM mount. He will be looking to pour pitch on his Perfect Pitch silicone form soon. TimC says he will want to pour pitch in about 4 weeks for his mirrors, hoping he can do it at the same time with TomW's perfected pitch pouring procedure.

TimC was working on the start of his From The Workshop Note #3. Also carrying on grinding the donated 8" mirror with 500 grit, while talking about the Giant Magellan Telescope mirrors being made at the University of Arizona. Seven 8m mirrors will be placed together to form the GMT. Mirrors are heated to about 1200C to melt the borosilicate, then cooled to about 1000C to resolidify, all the while the 27 foot diameter mirror is spun at about 1RPM to help form a parabolic surface.

The 8" grinding was going well until TimC noticed a scratch on the surface. Possibly some older larger grit bit that was caught behind the tool tiles had come out to leave the scratch? The tool and its tiles were examined from the backside and thoroughly cleaned. A bit more 500grit grinding and the scratch was disappearing. Examining the surface with the 8X loupe only a few internal bubbles (with shadows away from the LCD light source) could seen below the smoothing surface.

TimC,EdK,TomT

EdK brought in 14h? x 17w? framed astrophotography of M31, the (Princess) Andromeda Galaxy, created by Paul Winn...very beautiful. Ed is working on his Losmandy tripod adapter to the Celestron CGEM mount. He will be looking to pour pitch on his Perfect Pitch silicone form soon. TimC says he will want to pour pitch in about 4 weeks for his mirrors, hoping he can do it at the same time with TomW's perfected pitch pouring procedure.

TimC was working on the start of his From The Workshop Note #3. Also carrying on grinding the donated 8" mirror with 500 grit, while talking about the Giant Magellan Telescope mirrors being made at the University of Arizona. Seven 8m mirrors will be placed together to form the GMT. Mirrors are heated to about 1200C to melt the borosilicate, then cooled to about 1000C to resolidify, all the while the 27 foot diameter mirror is spun at about 1RPM to help form a parabolic surface.

The 8" grinding was going well until TimC noticed a scratch on the surface. Possibly some older larger grit bit that was caught behind the tool tiles had come out to leave the scratch? The tool and its tiles were examined from the backside and thoroughly cleaned. A bit more 500grit grinding and the scratch was disappearing. Examining the surface with the 8X loupe only a few internal bubbles (with shadows away from the LCD light source) could seen below the smoothing surface.

Wednesday, February 5, 2014

140204

140204 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TimC, EdK, JoeD, ChuckM, ChrisU

JoeD brought in the 6” AstroTech f/4 that he is modifying for portability: He has stiffened the tripod further and made a spotting tube with fishing wire for crosshairs. Tim consulting on further solutions for stiffening.

JoeD brought in the 6” AstroTech f/4 that he is modifying for portability: He has stiffened the tripod further and made a spotting tube with fishing wire for crosshairs. Tim consulting on further solutions for stiffening.

TomT discussed summer meetings with JerryW, need sign up sheet for member presenters. Jerry says he can always do a talk if not enough people volunteer.

TimC did a little more 500 Al2O3 grit grinding on the 8” donated mirror. JerryW checked the surface with the loupe and called for another hour to be sure.

TimC asking for suggestions for his next article, perhaps reviewing some telescope/mirror defintions; Jerry thinks covering one term might be enough. Joe suggested to focus on “choose your own” theme, e.g. how to design a telescope that meets an individual’s needs.

EdK will be making a smaller tool, using the Perfect Pitch silicone form, but waiting for it to arrive. He will be using chordal strokes with a 6.5” Tool. Ed consulting w/ Jerry on some other telescope factors.

JerryW working at home on the 6” secondary mirror for his Corrected Dahl Kirkham (CDK) 14.5” system. One test will be by laying desired convex mirror on ground concave glass and shining monochromatic light through them, looking for a light pattern. http://www.ceravolo.com/CDK_tech_talk.html

ChuckM asking Jerry about need for multiple dark frames for stacking photos with Photoshop CS4. Jerry converts to Fits files, using Nebulosity program? Jerry warns that hot pixels may depend on temperature of the camera chip as well. http://www.Astrometry.net is being used by Chuck to determine star field if unknown.

Attendees: TomT, JerryW, TimC, EdK, JoeD, ChuckM, ChrisU

JoeD brought in the 6” AstroTech f/4 that he is modifying for portability: He has stiffened the tripod further and made a spotting tube with fishing wire for crosshairs. Tim consulting on further solutions for stiffening.

JoeD brought in the 6” AstroTech f/4 that he is modifying for portability: He has stiffened the tripod further and made a spotting tube with fishing wire for crosshairs. Tim consulting on further solutions for stiffening.TomT discussed summer meetings with JerryW, need sign up sheet for member presenters. Jerry says he can always do a talk if not enough people volunteer.

TimC did a little more 500 Al2O3 grit grinding on the 8” donated mirror. JerryW checked the surface with the loupe and called for another hour to be sure.

TimC asking for suggestions for his next article, perhaps reviewing some telescope/mirror defintions; Jerry thinks covering one term might be enough. Joe suggested to focus on “choose your own” theme, e.g. how to design a telescope that meets an individual’s needs.

EdK will be making a smaller tool, using the Perfect Pitch silicone form, but waiting for it to arrive. He will be using chordal strokes with a 6.5” Tool. Ed consulting w/ Jerry on some other telescope factors.

JerryW working at home on the 6” secondary mirror for his Corrected Dahl Kirkham (CDK) 14.5” system. One test will be by laying desired convex mirror on ground concave glass and shining monochromatic light through them, looking for a light pattern. http://www.ceravolo.com/CDK_tech_talk.html

ChuckM asking Jerry about need for multiple dark frames for stacking photos with Photoshop CS4. Jerry converts to Fits files, using Nebulosity program? Jerry warns that hot pixels may depend on temperature of the camera chip as well. http://www.Astrometry.net is being used by Chuck to determine star field if unknown.

Friday, January 31, 2014

TimC From The Workshop #2...(Draft)

On 1/29/2014 8:41 AM, Tim Crawford wrote:

From The Workshop #2...(Draft)

Crafting a telescope mirror can be a rewarding endeavor. Once, in my earlier years I went downtown and bought a telescope mirror kit from Douglas Telescopics. I bought a 55gallon drum to use as a work top . I set it all up and opened Allyn Thompson's Making Your Own Telescope.... I was stunned ! It made no sense. I put everything away-for years! The reason for this short aside is to let you know it is not uncommon to be lost in the beginning when you try to do it a cappella. I strongly advise you to find someone to guide you, like you get in a workshop like ours. There are many in the group with hundreds of hours crafting mirrors. They have vast experience and can guide you through all aspects of crafting your own mirror.

So you are handed a round blank and another tool of let's say the same diameter. As in the previous letter, you will use a grinding medium between the two to grind a telescope mirror. Before you begin though, there is one important step to do. You must bevel the outer edge of your blank. You may use a carborundum sharpening stone to do this. Soak it in water and using a downward 45 degree angle, grind slowly the edge of your mirror. For purposes of these essays, I will use Pyrex as the material we use as a mirror. This bevel will prevent chipping of the edge of your Pyrex blank while grinding. The bevel should be at least 1/8th inch wide. Choose a workplace that has somewhat constant temperatures and a work surface that has strong support.

How does it all happen then? How do two flat surfaces become a perfect sphere and a perfect convex compliment of this sphere? The answer is an elegant one and a little obvious on hindsight. Let's not think so much about the abrasives here but instead, think of the two discs passing over one another. The disc on top just by its own weight has downward pressure on the lower disc. The upper disc is worn in the center and the lower disc is worn on the edges. But, let's think of it another way to further illustrate the process. If the upper disc is passed over the lower, using chordal strokes let's say, first a little to the right and then a little to the left, then the middle of the disc on top is getting worked full time, while the edges get a break when the disc is either right or left of center. The center has to wear more than the edges. Now, add one more element- controlled randomness. Sounds kind of contrarian but it is the most important. By walking around a worktop in one direction while turning the mirror the opposite direction while grinding, the discs become worked evenly, in fact perfectly. But, how deep do we make them? How do we stop from going deeper and deeper. Next edition we will cover this as well as terms you will likely use if you decide to grind your own optics.

From The Workshop #2...(Draft)

Crafting a telescope mirror can be a rewarding endeavor. Once, in my earlier years I went downtown and bought a telescope mirror kit from Douglas Telescopics. I bought a 55gallon drum to use as a work top . I set it all up and opened Allyn Thompson's Making Your Own Telescope.... I was stunned ! It made no sense. I put everything away-for years! The reason for this short aside is to let you know it is not uncommon to be lost in the beginning when you try to do it a cappella. I strongly advise you to find someone to guide you, like you get in a workshop like ours. There are many in the group with hundreds of hours crafting mirrors. They have vast experience and can guide you through all aspects of crafting your own mirror.

So you are handed a round blank and another tool of let's say the same diameter. As in the previous letter, you will use a grinding medium between the two to grind a telescope mirror. Before you begin though, there is one important step to do. You must bevel the outer edge of your blank. You may use a carborundum sharpening stone to do this. Soak it in water and using a downward 45 degree angle, grind slowly the edge of your mirror. For purposes of these essays, I will use Pyrex as the material we use as a mirror. This bevel will prevent chipping of the edge of your Pyrex blank while grinding. The bevel should be at least 1/8th inch wide. Choose a workplace that has somewhat constant temperatures and a work surface that has strong support.

How does it all happen then? How do two flat surfaces become a perfect sphere and a perfect convex compliment of this sphere? The answer is an elegant one and a little obvious on hindsight. Let's not think so much about the abrasives here but instead, think of the two discs passing over one another. The disc on top just by its own weight has downward pressure on the lower disc. The upper disc is worn in the center and the lower disc is worn on the edges. But, let's think of it another way to further illustrate the process. If the upper disc is passed over the lower, using chordal strokes let's say, first a little to the right and then a little to the left, then the middle of the disc on top is getting worked full time, while the edges get a break when the disc is either right or left of center. The center has to wear more than the edges. Now, add one more element- controlled randomness. Sounds kind of contrarian but it is the most important. By walking around a worktop in one direction while turning the mirror the opposite direction while grinding, the discs become worked evenly, in fact perfectly. But, how deep do we make them? How do we stop from going deeper and deeper. Next edition we will cover this as well as terms you will likely use if you decide to grind your own optics.

140128

140128 Telescope Workshop Notes

TimC, DmitriiZ, TomT

Tim continued working 500grit on the donated 8" mirror, while being interrupted with questions on dental technician techniques.

Tim continued working 500grit on the donated 8" mirror, while being interrupted with questions on dental technician techniques.

Dmitrii, after weighting his pitched tool to take the shape of the mirror, put in about 1 hour of polishing on his 12.5" mirror and kept the conversations rolling.

Larger pictures/video here:

http://www.flickr.com/photos/27241501@N03/sets/72157640342892244/

TimC, DmitriiZ, TomT

Tim continued working 500grit on the donated 8" mirror, while being interrupted with questions on dental technician techniques.

Tim continued working 500grit on the donated 8" mirror, while being interrupted with questions on dental technician techniques.Dmitrii, after weighting his pitched tool to take the shape of the mirror, put in about 1 hour of polishing on his 12.5" mirror and kept the conversations rolling.

Larger pictures/video here:

http://www.flickr.com/photos/27241501@N03/sets/72157640342892244/

Thursday, January 30, 2014

Tim's notes From the Workshop #1+

On 1/19/2014 9:35 PM, Tim Crawford wrote:

> Greetings once again,

> There will be a workshop this week, January 21, at the Broder,from 7:30pm till 9. This week I will continue to grind the donated mirror. It is coming along famously. I will start to use 500 grit this week. It will not be to long now. It is now time to start the design of the new scope. Thanks to Dr. Tom and Dr. Jerry I am able to easily see these projects come to fruition. If you are able, come I'm by and see us. Bring your ideas, projects or questions.

> T

On 1/13/2014 8:06 AM, Tim Crawford wrote:

> Greetings all,

> I am scheduling a workshop this Tuesday, January 14th, at the Broder Building starting at 7:30pm. Please feel free to drop in if you can make it. I really don't have a specific topic for the evening but I would like to continue the fine grinding on the donated 8". I do have a question for you all. What would it take to create a permanent dedicated set up to do, say, asteroid occultation studies? Make this guesstimating with the precondition that a location is already available. It can also be remote setup with remote access. Do not consider cost, but instead what hardware/software would it take?

> T

January, 2014 SBAU newsletter:

From the Workshop #1...

Tim Crawford

Greetings from the workshop! Our mirror class, originally created by our own Tom Whittemore, is now in its eleventh year! It seems like just yesterday we were at the Broder Building gathering for our first encounter with grinding a working mirror to be integrated into a hand-crafted Newtonian-type telescope. For many of us these are Dobsonian scopes utilizing John Dobson's famous, simple and elegantly-designed scopes.

Our goal is to keep you abreast of the most current techniques which Amateur Telescope Makers(ATMs) can offer. Now, most of you are very proficient with telescopes. Still, I hope to give you a first-hand example of what may happen when you are encouraged to make your own telescope mirror and, when this is done, to design and build a telescope.

First you are handed an 8” disc of Pyrex. Next you are given a ceramic grinding tool made essentially from bathroom tile. Since your grinding tool has the same hardness as does your mirror, the tool will wear down the glass when silicon carbide is used as an abrasive between the two. This is how you start to make a truly fine mirror! Eleven years ago, along with some patient instruction from Tom, this is all we were given. But, in the meantime, many of us went on to complete our mirror-and-telescope making projects.

In future editions of the “joys of mirror making and telescope building,” I will get into some of the finer details of making a research-grade telescope mirror. Please stay tuned! Happy New Year!

> Greetings once again,

> There will be a workshop this week, January 21, at the Broder,from 7:30pm till 9. This week I will continue to grind the donated mirror. It is coming along famously. I will start to use 500 grit this week. It will not be to long now. It is now time to start the design of the new scope. Thanks to Dr. Tom and Dr. Jerry I am able to easily see these projects come to fruition. If you are able, come I'm by and see us. Bring your ideas, projects or questions.

> T

On 1/13/2014 8:06 AM, Tim Crawford wrote:

> Greetings all,

> I am scheduling a workshop this Tuesday, January 14th, at the Broder Building starting at 7:30pm. Please feel free to drop in if you can make it. I really don't have a specific topic for the evening but I would like to continue the fine grinding on the donated 8". I do have a question for you all. What would it take to create a permanent dedicated set up to do, say, asteroid occultation studies? Make this guesstimating with the precondition that a location is already available. It can also be remote setup with remote access. Do not consider cost, but instead what hardware/software would it take?

> T

January, 2014 SBAU newsletter:

From the Workshop #1...

Tim Crawford

Greetings from the workshop! Our mirror class, originally created by our own Tom Whittemore, is now in its eleventh year! It seems like just yesterday we were at the Broder Building gathering for our first encounter with grinding a working mirror to be integrated into a hand-crafted Newtonian-type telescope. For many of us these are Dobsonian scopes utilizing John Dobson's famous, simple and elegantly-designed scopes.

Our goal is to keep you abreast of the most current techniques which Amateur Telescope Makers(ATMs) can offer. Now, most of you are very proficient with telescopes. Still, I hope to give you a first-hand example of what may happen when you are encouraged to make your own telescope mirror and, when this is done, to design and build a telescope.

First you are handed an 8” disc of Pyrex. Next you are given a ceramic grinding tool made essentially from bathroom tile. Since your grinding tool has the same hardness as does your mirror, the tool will wear down the glass when silicon carbide is used as an abrasive between the two. This is how you start to make a truly fine mirror! Eleven years ago, along with some patient instruction from Tom, this is all we were given. But, in the meantime, many of us went on to complete our mirror-and-telescope making projects.

In future editions of the “joys of mirror making and telescope building,” I will get into some of the finer details of making a research-grade telescope mirror. Please stay tuned! Happy New Year!

Thursday, January 16, 2014

140114

140114 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TimC, EdK, JoeD, ChrisU, DavidH

JoeD brought in 6” AstroTech f/4 that he is modifying for portability: http://www.buytelescopes.com/astro-tech-6-f4-imaging-newtonian-optical-tube . He moved the focuser position farther out since he will not be using a camera. He has made a perpendicular plywood mount with three hand holds and swivel bottom on a heavy duty photographic tripod (Manfrotto). The mount can also stand flat on a table with its slippery feet to allow horizontal movement without a tripod. First light with the new mount was tonight looking at the Moon and Jupiter and its moons. Some diffraction on objects, possibly from large secondary mirror, that Joe says was used to make the telescope more useful for astrophotography. Also, Joe will try to reduce some wobble of the tripod mount and the bottom plate attachments.

TomT mentioned that summer meetings pushed by JerryW will be attempted, hopefully members will do them, which was also suggested by Jerry. We can have outsiders come in as well, and the backup is to use videos taken off YouTube or astronomy DVD programs.

TimC did a little more 320 Al2O3 grit grinding on the 8” donated mirror. JerryW checked the surface with the loupe and called it good. Tim will try to find some 500 grit, Aluminum Oxide.

EdK brought in mirror, but no testing setup tonight. Ed will be modifying his polishing stroke to chordal to remove the turned down edge.

DavidH’s old Celestron German Equatorial Mount that fell off table last week and bent a wormgear shaft, already has been fixed by Art Harris.

TimC-will be writing another article for newsletter, talking about steps of understanding telescope functions, but wants help from JerryW and TomW final editing. Tim wants to get around to describing the earliest telescopes and history of telescopes.

TimC-will be writing another article for newsletter, talking about steps of understanding telescope functions, but wants help from JerryW and TomW final editing. Tim wants to get around to describing the earliest telescopes and history of telescopes.

JerryW-says think of Power as diameter increase, 100X means Jupiter would look 100X bigger than what the human eye can see alone. He discussed apparent field of view (field stop edge in the back of the eyepiece) vs. field of view thru the telescope, which depends on focal length of telescope divided by eyepiece focal length.

More photos of tonight's session: http://www.flickr.com/photos/27241501@N03/sets/72157639851024855/

Attendees: TomT, JerryW, TimC, EdK, JoeD, ChrisU, DavidH

JoeD brought in 6” AstroTech f/4 that he is modifying for portability: http://www.buytelescopes.com/astro-tech-6-f4-imaging-newtonian-optical-tube . He moved the focuser position farther out since he will not be using a camera. He has made a perpendicular plywood mount with three hand holds and swivel bottom on a heavy duty photographic tripod (Manfrotto). The mount can also stand flat on a table with its slippery feet to allow horizontal movement without a tripod. First light with the new mount was tonight looking at the Moon and Jupiter and its moons. Some diffraction on objects, possibly from large secondary mirror, that Joe says was used to make the telescope more useful for astrophotography. Also, Joe will try to reduce some wobble of the tripod mount and the bottom plate attachments.

TomT mentioned that summer meetings pushed by JerryW will be attempted, hopefully members will do them, which was also suggested by Jerry. We can have outsiders come in as well, and the backup is to use videos taken off YouTube or astronomy DVD programs.

TimC did a little more 320 Al2O3 grit grinding on the 8” donated mirror. JerryW checked the surface with the loupe and called it good. Tim will try to find some 500 grit, Aluminum Oxide.

EdK brought in mirror, but no testing setup tonight. Ed will be modifying his polishing stroke to chordal to remove the turned down edge.

DavidH’s old Celestron German Equatorial Mount that fell off table last week and bent a wormgear shaft, already has been fixed by Art Harris.

TimC-will be writing another article for newsletter, talking about steps of understanding telescope functions, but wants help from JerryW and TomW final editing. Tim wants to get around to describing the earliest telescopes and history of telescopes.

TimC-will be writing another article for newsletter, talking about steps of understanding telescope functions, but wants help from JerryW and TomW final editing. Tim wants to get around to describing the earliest telescopes and history of telescopes.JerryW-says think of Power as diameter increase, 100X means Jupiter would look 100X bigger than what the human eye can see alone. He discussed apparent field of view (field stop edge in the back of the eyepiece) vs. field of view thru the telescope, which depends on focal length of telescope divided by eyepiece focal length.

More photos of tonight's session: http://www.flickr.com/photos/27241501@N03/sets/72157639851024855/

Friday, January 10, 2014

140107

140107 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TimC, EdK, ChrisU, DavidH

TimC talking again about bringing in samples of Telescope Workshop stuff to monthly meetings, but tonight’s suggestions were to setup for a full meeting, during the long light evenings of the summer, discussing mirror and telescope creation and astrophotography. Gathering questions that members want to have answered ahead of time would determine meeting coverage.

TimC did a little more 320 grit grinding on the 8” donated mirror.

EdK brought in mirror, but no testing setup tonight. Ed has put in another 16 hours of polishing trying to widen spherical surface. See his email.

DavidH brought in the old Celestron German Equatorial Mount. David says too much grease and also that one piece was not screwed in far enough that caused the concern about too much slop in the wormgear. Now Jerry and David looking at drive system, Jerry brought in his drive controller, cables, drives from a Vixen GPD (great Polaris) mount, with a 12V battery cigarette lighter connection (Kendrick wheelchair type battery). Unfortunately, gear drive fell off table and bent a wormgear shaft. Art Harris was suggested as the man to consult with for repair.

DavidH brought in the old Celestron German Equatorial Mount. David says too much grease and also that one piece was not screwed in far enough that caused the concern about too much slop in the wormgear. Now Jerry and David looking at drive system, Jerry brought in his drive controller, cables, drives from a Vixen GPD (great Polaris) mount, with a 12V battery cigarette lighter connection (Kendrick wheelchair type battery). Unfortunately, gear drive fell off table and bent a wormgear shaft. Art Harris was suggested as the man to consult with for repair.

ChrisU brought in his “Flaming Tomato” Dobsonian telescope and mount. He is putting on a home textured formica strip on the Declination circles for friction or stiction (static+friction?).

Attendees: TomT, JerryW, TimC, EdK, ChrisU, DavidH

TimC talking again about bringing in samples of Telescope Workshop stuff to monthly meetings, but tonight’s suggestions were to setup for a full meeting, during the long light evenings of the summer, discussing mirror and telescope creation and astrophotography. Gathering questions that members want to have answered ahead of time would determine meeting coverage.

TimC did a little more 320 grit grinding on the 8” donated mirror.

EdK brought in mirror, but no testing setup tonight. Ed has put in another 16 hours of polishing trying to widen spherical surface. See his email.

DavidH brought in the old Celestron German Equatorial Mount. David says too much grease and also that one piece was not screwed in far enough that caused the concern about too much slop in the wormgear. Now Jerry and David looking at drive system, Jerry brought in his drive controller, cables, drives from a Vixen GPD (great Polaris) mount, with a 12V battery cigarette lighter connection (Kendrick wheelchair type battery). Unfortunately, gear drive fell off table and bent a wormgear shaft. Art Harris was suggested as the man to consult with for repair.

DavidH brought in the old Celestron German Equatorial Mount. David says too much grease and also that one piece was not screwed in far enough that caused the concern about too much slop in the wormgear. Now Jerry and David looking at drive system, Jerry brought in his drive controller, cables, drives from a Vixen GPD (great Polaris) mount, with a 12V battery cigarette lighter connection (Kendrick wheelchair type battery). Unfortunately, gear drive fell off table and bent a wormgear shaft. Art Harris was suggested as the man to consult with for repair.

ChrisU brought in his “Flaming Tomato” Dobsonian telescope and mount. He is putting on a home textured formica strip on the Declination circles for friction or stiction (static+friction?).

Wednesday, December 11, 2013

131210 Telescope Workshop notes

131210 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TimC, EdK, ChrisU, David/MadelineH

JerryW reviewing EdK mirror Foucault photos and describing strokes needed. EdK has been doing the chordal stroke trying to lower outer surface. Center seems to be more spherical. Jerry says matching Ronchi diagram is better than Foucault for determining shape. Later, W stroke (tall in center, tool on top of mirror) will be used for final polishing to parabola.

markers in the photos are at:

1) 31% = 1.9375 inches

2) 55% = 3.4375 inches

3) 70% = 4.375 inches

4) 84% = 5.25 inches

5) 95% = 5.9375 inches

TimC suggesting bringing in samples of Telescope Workshop stuff to monthly meetings. He will bring subject up at planning meeting this Saturday. He has a 6” donated mirror from Doug? that needs to be refinished if someone will show some interest in attending the telescope workshop. Tim explaining and showing David and Madeline the grinding of the 8 inch mirror. TimC continued 320 grit grinding on the donated 8” mirror.

EdK showed us his new Celestron CGEM Pro control module with lots of ports on it. http://www.optcorp.com/celestron-cge-pro-equatorial-mount.html

He will be mounting this on a Losmandy G11 pedestal? mount.

DavidH brought in the old Celestron German Equatorial Mount. It was binding so David tried to check out the wormgears. Seems maybe too much white grease added. Jerry thinks wormgear shaft needs some spacing Teflon washers to keep it properly in place at the gear to prevent slack when reversing direction. Also, some 5 pin DIN cables are needed to connect the motors to the controller. Art Harris may be contacted for his expertise for both situations.

ChrisU brought in his flaming tomato dobsonian telescope and mount. TimC laser collimated the telescope for him. We checked out the perfection of Mike Farris’s polishing and the aligned unit by looking at the Moon and the straight wall. The mount worked well.

Attendees: TomT, JerryW, TimC, EdK, ChrisU, David/MadelineH

JerryW reviewing EdK mirror Foucault photos and describing strokes needed. EdK has been doing the chordal stroke trying to lower outer surface. Center seems to be more spherical. Jerry says matching Ronchi diagram is better than Foucault for determining shape. Later, W stroke (tall in center, tool on top of mirror) will be used for final polishing to parabola.

markers in the photos are at:

1) 31% = 1.9375 inches

2) 55% = 3.4375 inches

3) 70% = 4.375 inches

4) 84% = 5.25 inches

5) 95% = 5.9375 inches

TimC suggesting bringing in samples of Telescope Workshop stuff to monthly meetings. He will bring subject up at planning meeting this Saturday. He has a 6” donated mirror from Doug? that needs to be refinished if someone will show some interest in attending the telescope workshop. Tim explaining and showing David and Madeline the grinding of the 8 inch mirror. TimC continued 320 grit grinding on the donated 8” mirror.

EdK showed us his new Celestron CGEM Pro control module with lots of ports on it. http://www.optcorp.com/celestron-cge-pro-equatorial-mount.html

He will be mounting this on a Losmandy G11 pedestal? mount.

DavidH brought in the old Celestron German Equatorial Mount. It was binding so David tried to check out the wormgears. Seems maybe too much white grease added. Jerry thinks wormgear shaft needs some spacing Teflon washers to keep it properly in place at the gear to prevent slack when reversing direction. Also, some 5 pin DIN cables are needed to connect the motors to the controller. Art Harris may be contacted for his expertise for both situations.

ChrisU brought in his flaming tomato dobsonian telescope and mount. TimC laser collimated the telescope for him. We checked out the perfection of Mike Farris’s polishing and the aligned unit by looking at the Moon and the straight wall. The mount worked well.

Saturday, December 7, 2013

131203

131203 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, TomW, TimC, DmitriiZ, EdK, ChrisU

EdK’s mirror examined again after another 7 hours of home polishing with TomW’s Ronchi tester. Center is slowing expanding to spherical surface, but TomW thinks more pressure is needed for faster change. Lighter lapping tool is over mirror as TomW says heavy mirror over tool would be bad for mirror. Several positions of the tester for curvature of radius were tried. Using the Ronchi with only one line being used like a knife edge of a Foucault tester shows, per Jerry, two gray areas that have the same radius of curvature, one in the center and one out beyond the 70% area. Jerry gave EdK a list of the zones that he uses.

TomT loaned his EasyTesters for collimation testing to JerryW. TomT also showed the Bahtinov mask purchased via Amazon, that helps to find exact focus for a telescope. The size he had was for 5-8.5” mirror appatures.

TimC continued 320 grit grinding on the donated 8” mirror, while Dmitrii worked on polishing his 12.5” mirror.

Attendees: TomT, JerryW, TomW, TimC, DmitriiZ, EdK, ChrisU

EdK’s mirror examined again after another 7 hours of home polishing with TomW’s Ronchi tester. Center is slowing expanding to spherical surface, but TomW thinks more pressure is needed for faster change. Lighter lapping tool is over mirror as TomW says heavy mirror over tool would be bad for mirror. Several positions of the tester for curvature of radius were tried. Using the Ronchi with only one line being used like a knife edge of a Foucault tester shows, per Jerry, two gray areas that have the same radius of curvature, one in the center and one out beyond the 70% area. Jerry gave EdK a list of the zones that he uses.

TomT loaned his EasyTesters for collimation testing to JerryW. TomT also showed the Bahtinov mask purchased via Amazon, that helps to find exact focus for a telescope. The size he had was for 5-8.5” mirror appatures.

TimC continued 320 grit grinding on the donated 8” mirror, while Dmitrii worked on polishing his 12.5” mirror.

Wednesday, November 27, 2013

131126

131126 Telescope Workshop notes 730-9p Tuesday evening

Attendees: TomT, JerryW, David/MadelineH

Jerry brought in collimator devices: Orion lasermate deluxe and a Pro-Optic Holographic, plus a Orion 2” centering device to make sure the collimator is centered in the focuser. https://www.astronomics.com/glatter-1-25-inch-grid-hologram-single-beam-635nm-laser-collimator_p10849.aspx .

Jerry discussed Fourier Transforms and how the brain/eyes work when TomT asked the question of why watching the CNN news line caused him to see a distortion on his computer screen when looking away from the TV. http://en.wikipedia.org/wiki/Fourier_series

David, a new member of the SBAU, brought in a German Equatorial mount that his dad had used with a C8 telescope. (Something like this: http://www.vixenoptics.com/mounts/gp2mount.htm .) He wanted to know how to use it, so Jerry wrote a list of steps to setup the mount. TomT suggested watching YouTube videos on telescope setup (like this: http://www.youtube.com/watch?v=9YtUGCnGLXo ). Jerry says this GEM most likely has steppers motors inside. David’s father had attached plastic gearing and position encoders, which now had broken pins, to determine position. The mount was purchased in the late 1980’s. It seems to be an old Vixen Japanese mount. He will bring in the complete telescope assembly for the next TW meeting.

David is working on a Phd at UCSB in childhood education spatial reasoning (also see www.hallowelltutoring.com). His 5 year old daughter was with him tonight, Madeline, and she said she has pictures of planets in her room at home (plus a 18 month old brother)!

Attendees: TomT, JerryW, David/MadelineH

Jerry brought in collimator devices: Orion lasermate deluxe and a Pro-Optic Holographic, plus a Orion 2” centering device to make sure the collimator is centered in the focuser. https://www.astronomics.com/glatter-1-25-inch-grid-hologram-single-beam-635nm-laser-collimator_p10849.aspx .

Jerry discussed Fourier Transforms and how the brain/eyes work when TomT asked the question of why watching the CNN news line caused him to see a distortion on his computer screen when looking away from the TV. http://en.wikipedia.org/wiki/Fourier_series

David, a new member of the SBAU, brought in a German Equatorial mount that his dad had used with a C8 telescope. (Something like this: http://www.vixenoptics.com/mounts/gp2mount.htm .) He wanted to know how to use it, so Jerry wrote a list of steps to setup the mount. TomT suggested watching YouTube videos on telescope setup (like this: http://www.youtube.com/watch?v=9YtUGCnGLXo ). Jerry says this GEM most likely has steppers motors inside. David’s father had attached plastic gearing and position encoders, which now had broken pins, to determine position. The mount was purchased in the late 1980’s. It seems to be an old Vixen Japanese mount. He will bring in the complete telescope assembly for the next TW meeting.

David is working on a Phd at UCSB in childhood education spatial reasoning (also see www.hallowelltutoring.com). His 5 year old daughter was with him tonight, Madeline, and she said she has pictures of planets in her room at home (plus a 18 month old brother)!

Subscribe to:

Posts (Atom)